As its name indicates the formation of ears at the free edges of a deep drawn cylindrical cup is known as earing defect fig.

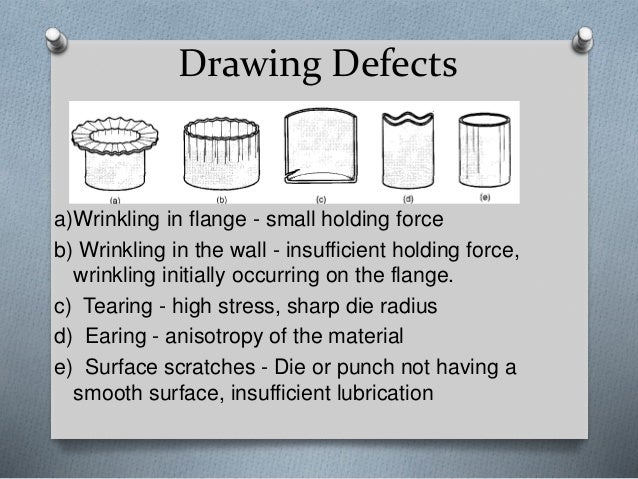

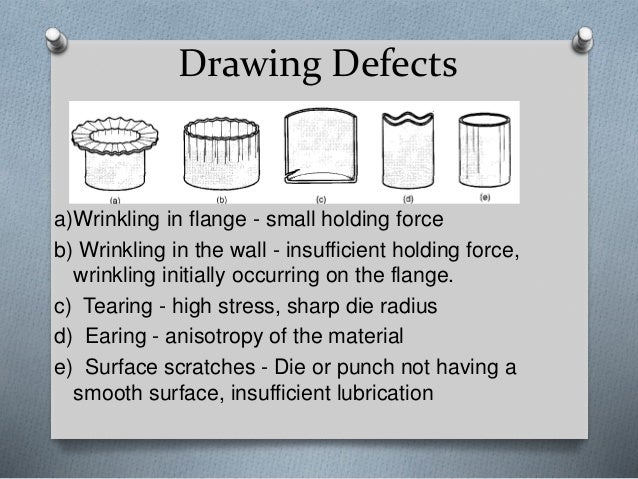

Defects in sheet metal drawing.

How to dimension a drawing.

One is the improper handling another one is the elasticity of sheet metal forming materials.

Defects in drawing process.

Tearing is one of the most common defects.

Excessive thinning in areas of the sheet metal is also an unwanted defect.

Failure of sheet metal parts during deep drawing processes usually takes place in the form of wrinkling or tearing.

The main reasons for the cracking are over stretching or stress concentration.

During this process the blank sheet will develop defects if the process parameters are not selected properly.

Wrinkles splits and springback are the three most common defects encountered during sheet metal stamping.

Sheet metal stamping drawing car industry 90million cars and commercial vehicles produced worldwide in 2014.

Defects that occur during deep drawing of sheet metal can be controlled by careful regulation of process factors.

One of the primary defects that occurs in deep drawing operations is the wrinkling of sheet metal material generally in the wall or flange of the part.

The sheet metal cleat the work of this problem will consist in laying out to full size the views and pattern for a galvanized sheet metal cleat.

Excessive thinning thickening of the sheet during forming.

Defects that occur during deep drawing of sheet metal can be controlled by careful regulation of process factors.

Springback or final part deviation from nominal incorrect process or number of forming tools.

Causes of these are mostly too high or improper force distribution and material considerations.

Incorrect blank shape and or size.

Tearing is one of the most common defects.

Predict part defects tearing wrinkling dimensional inaccuracy and propose.

Causes of these are mostly too high or improper force distribution and material considerations.

Stamping auto body panels 3 to 5 dies each prototype dies 50 000.

In making the layout for this cleat the following points must be kept in mind.

Accuracy in the use of the scale rule.

There are two reasons behind this defect.

Excessive thinning in areas of the sheet metal is also an unwanted defect.

This defect is caused by the anisotropy of the sheet metal.

The reason behind it is that welding positions are misaligned.